Call Us

08045479560

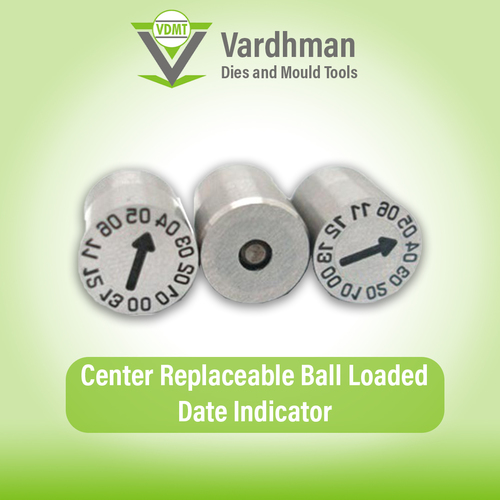

Center Replaceable Ball Loaded

40 INR

Product Details:

- Product Type Center Replaceable Ball Loaded

- Usage Industries

- Mould Base Mould base

- Color Silver

- Size Surface Finish: 0.1 micron -.04 micron

- Length 500 1000 mm Millimeter (mm)

- Core Material SUS 420

- Click to View more

X

Center Replaceable Ball Loaded Price And Quantity

- 10 Piece

- 40 INR

Center Replaceable Ball Loaded Product Specifications

- Surface Finish: 0.1 micron -.04 micron

- SUS 420

- 500 1000 mm Millimeter (mm)

- 1 year

- Center Replaceable Ball Loaded

- Steel

- Industries

- Mould base

- Silver

Center Replaceable Ball Loaded Trade Information

- Cash Advance (CA) Cash in Advance (CID) Cheque

- 10000 Piece Per Week

- 10 Days

- Carton packaging / As per clients requirement.

- All India

- We provide Test & hardness Certificate also Nsic and ISO Certified.

Product Description

The Center Replaceable Ball Loaded component is a versatile and robust part used extensively in various tooling, moulding, and die-casting processes. Designed and manufactured by Vardhman Dies & Mould Tools, this component ensures smooth and precise operation while enhancing the performance and longevity of moulding and die-casting systems.

Key Features of Center Replaceable Ball Loaded

- Durable Construction: Made from high-quality materials, the center replaceable ball-loaded components are designed for high wear resistance, ensuring long-lasting performance even in tough industrial environments.

- Easy Replacement: The innovative design allows for easy replacement of the central ball mechanism without needing to replace the entire assembly. This offers a cost-effective solution and reduces downtime during maintenance.

- Smooth Functioning: The ball-loaded mechanism ensures smooth, consistent movement, reducing friction and ensuring the precision required in various industrial applications.

- High Load Capacity: Engineered to handle high-pressure environments, this component effectively supports heavy loads without compromising performance or structural integrity.

- Precise Alignment: The ball-loaded system maintains optimal alignment, ensuring that the parts are consistently in the right position for precise operations.

- Corrosion Resistance: The materials used are resistant to corrosion and wear, enhancing the component's lifespan and minimizing the need for frequent maintenance.

Advantages of Center Replaceable Ball Loaded

- Cost Efficiency: The replaceable design ensures you only need to replace the ball center, reducing maintenance costs and extending the overall life of the equipment.

- Enhanced Performance: The ball-loaded mechanism provides smoother movements and reduces friction, improving the accuracy and efficiency of the overall tooling system.

- Longer Operational Life: With high-quality construction and corrosion resistance, the Center Replaceable Ball Loaded component is designed for prolonged use, offering durability and reliability.

- Ease of Maintenance: Its replaceable central ball feature simplifies maintenance and minimizes downtime, helping you keep your production processes running smoothly.

- Flexibility: The component can be customized to meet the specific needs of different industrial applications, ensuring optimal performance in various tooling and moulding systems.

Applications of Center Replaceable Ball Loaded

- Injection Moulding: In injection moulding, this component ensures that the moulds move smoothly and precisely, contributing to the consistency of the final product.

- Die Casting: The Center Replaceable Ball Loaded part is used in die-casting applications to maintain precise alignment, improve pressure distribution, and enhance overall product quality.

- Plastic and Rubber Moulding: In the production of plastic and rubber parts, this component ensures even pressure and smooth movement, minimizing defects and ensuring uniformity in the finished products.

- Automotive Manufacturing: Used in automotive manufacturing for precise moulding of components, this ball-loaded mechanism ensures optimal operation and accurate results in high-volume production.

- Electronics Manufacturing: The precision of the ball-loaded component makes it ideal for use in electronics manufacturing, where small, intricate components require highly accurate tooling and alignment.

Why Choose Vardhman Dies & Mould Tools?

- Superior Quality: Our components are made with the highest quality materials and are engineered for long-lasting performance, even under the most demanding conditions.

- Tailored Solutions: We understand that every industry has unique needs, and we offer customizable solutions to meet the specific requirements of your tooling and moulding applications.

- Industry Expertise: With years of experience in the field, Vardhman Dies & Mould Tools has built a reputation for excellence and innovation in providing high-performance products.

- Global Reach: Serving clients across the globe, we ensure timely delivery and consistent quality no matter where you're located.

- Reliability: Our components are designed for reliable, long-term use, making them a trusted choice for companies seeking to improve their production efficiency and reduce downtime.

Contact Us

- Website: www.vardhmandiesandmouldtools.com

- WhatsApp: Click to Chat

- Social Media:

For more information on Center Replaceable Ball Loaded components and other innovative tooling solutions, get in touch with Vardhman Dies & Mould Tools today.

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free