Call Us

08045479560

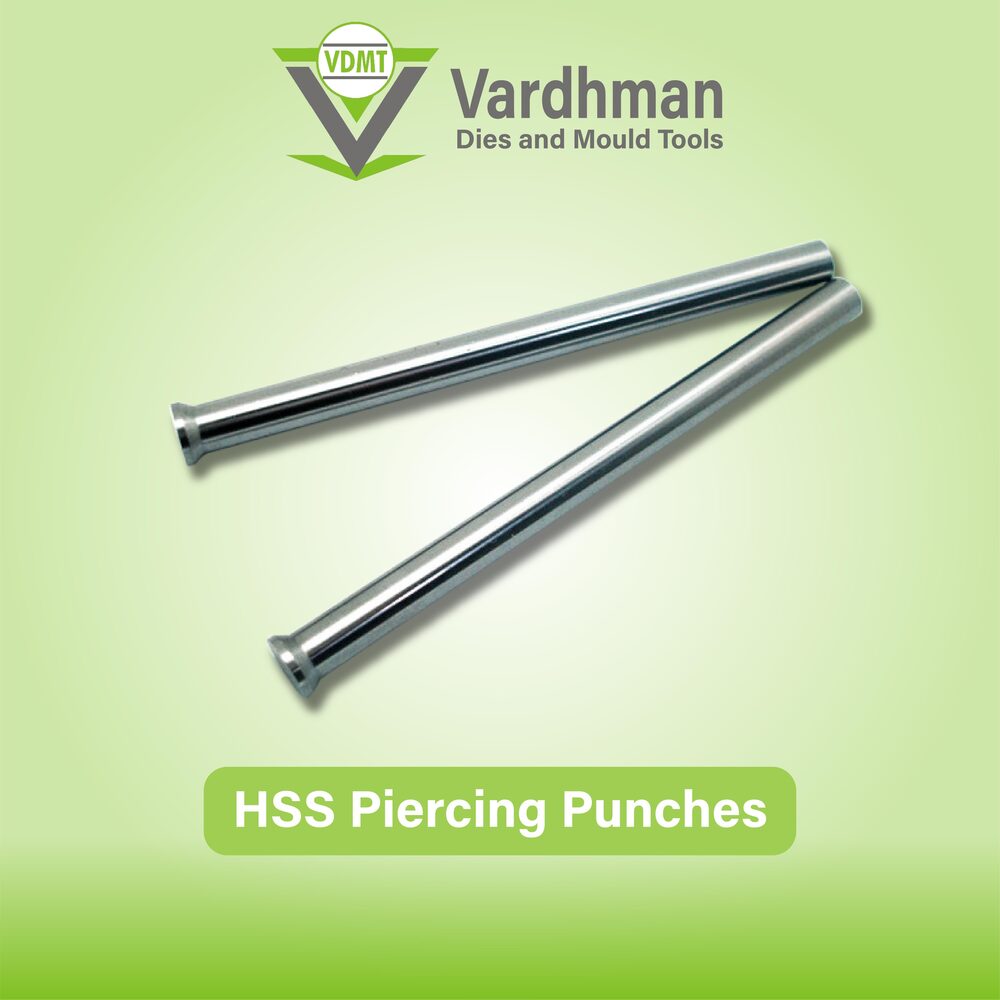

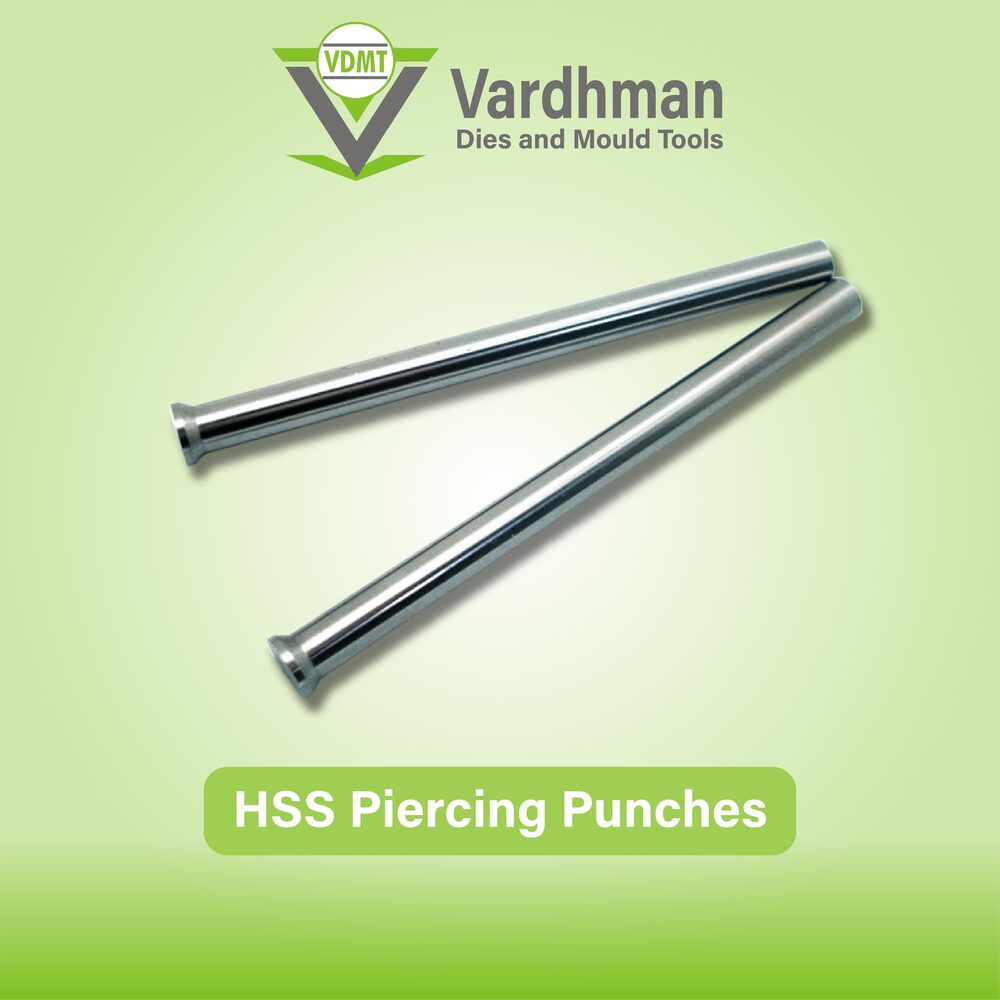

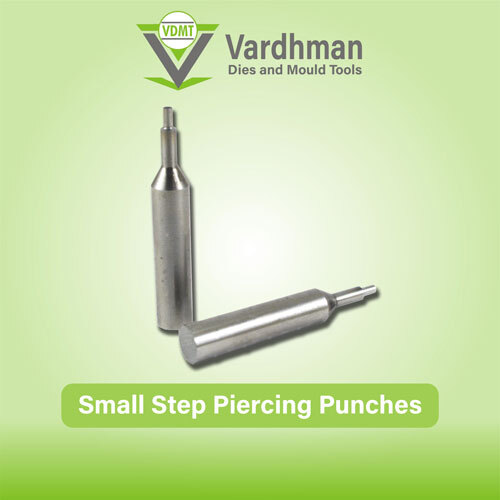

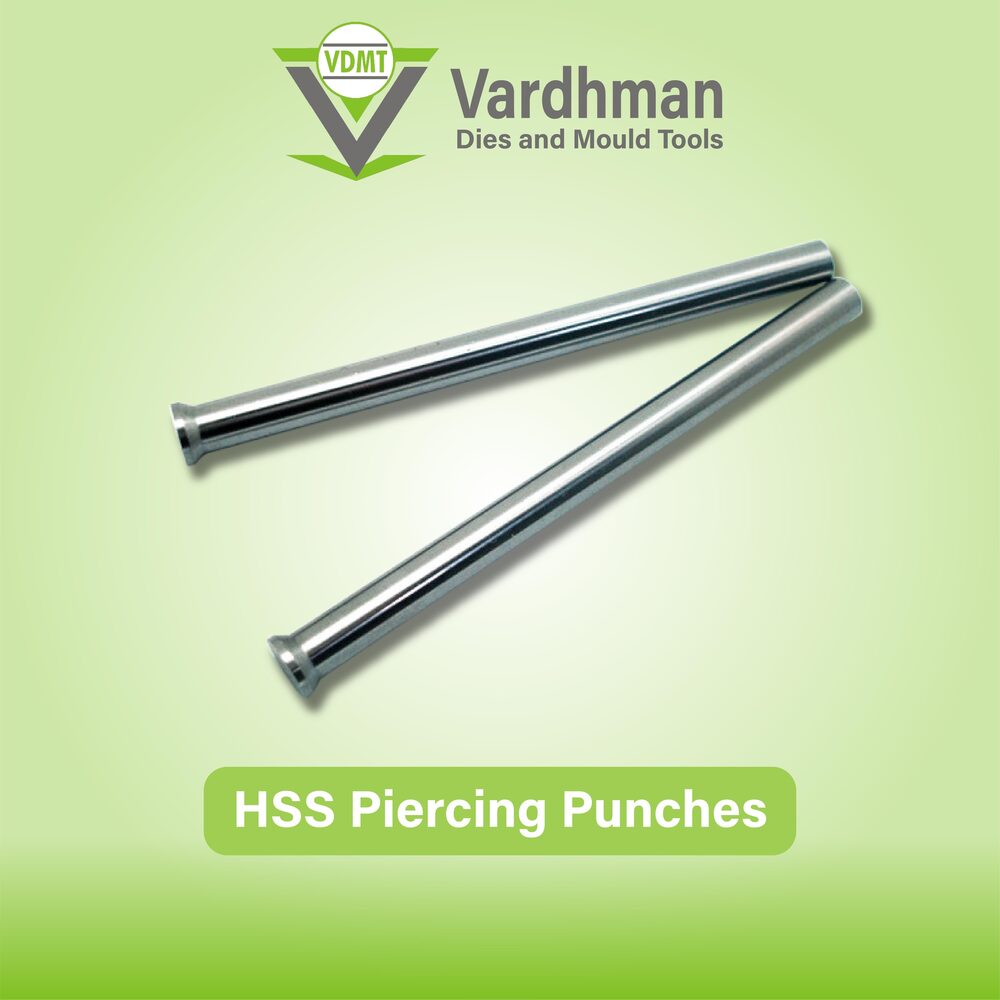

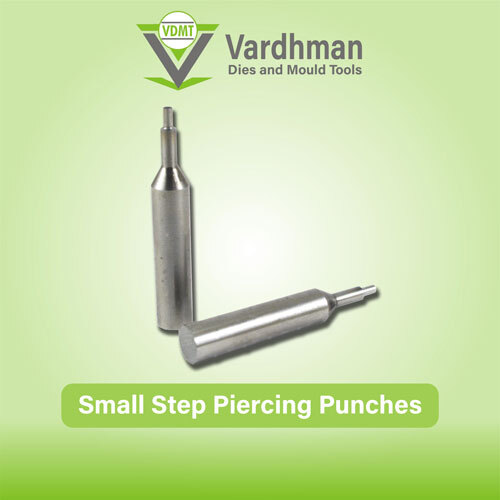

HSS Piercing Punches

550 INR/Unit

Product Details:

- Size 0.2 mm 50 mm dia

- Working Process Punching

- Usage Engineering industry

- Core Material HSS M2 M42- M35

- Color steel , silver

- Product Type HSS Piercing Punches

- Length 50 mm / 70 mm / 80 mm / 100 mm / customised Millimeter (mm)

- Click to View more

X

HSS Piercing Punches Price And Quantity

- 20 Unit

- 550 INR/Unit

HSS Piercing Punches Product Specifications

- Punching

- 0.2 mm 50 mm dia

- Punching Mould

- HSS Piercing Punches

- 50 mm / 70 mm / 80 mm / 100 mm / customised Millimeter (mm)

- steel , silver

- HSS M2 M42- M35

- Engineering industry

HSS Piercing Punches Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 Unit Per Week

- 7 Days

- Carton packaging / As per client's requirement.

- All India

- We provide Test & hardness Certificate also NSIC and ISO Certified.

Product Description

Vardhman Dies & Mould Tools HSS Piercing Punches Features & Advantages: Manufactured from High-Speed Steel (HSS) for enhanced durability and precision High tensile strength with seamless finishing Excellent wear resistance for prolonged tool life Capable of withstanding high temperatures and heavy-duty operations Corrosion-resistant, rustproof, and long-lasting High hardness and superior abrasion resistance Applications: Used in sheet metal fabrication for precise hole punching Essential in piercing and blanking operations Commonly applied in die and mould manufacturing Suitable for automotive, aerospace, and industrial tooling Vardhman Dies & Mould Tools is a trusted manufacturer, supplier, and exporter of HSS Piercing Punches in India. Our products are crafted using advanced manufacturing techniques and high-quality materials to ensure optimal performance and longevity.FAQs of HSS Piercing Punches:

Q: What is the shaping mode of HSS Piercing Punches?

A: The shaping mode of HSS Piercing Punches is Punching Mould.Q: What material is used for the core of HSS Piercing Punches?

A: The core material used for HSS Piercing Punches is HSS M2, M42, and M35.Q: What is the size range available for HSS Piercing Punches?

A: HSS Piercing Punches are available in sizes ranging from 0.2 mm to 50 mm in diameter.Q: What are the length options provided for HSS Piercing Punches?

A: The length options for HSS Piercing Punches include 50 mm, 70 mm, 80 mm, 100 mm, or customised lengths.Q: What is the primary usage of HSS Piercing Punches?

A: HSS Piercing Punches are primarily used in the engineering industry for punching processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese